Catalog

-

Catalog

- Agriculture

- Apparel

- Automobiles & Motorcycles

- Beauty & Personal Care

- Business Services

- Chemicals

- Construction & Real Estate

- Consumer Electronics

- Electrical Equipment & Supplies

- Electronic Components & Supplies

- Energy

- Environment

- Excess Inventory

- Fashion Accessories

- Food & Beverage

- Furniture

- Gifts & Crafts

- Hardware

- Health & Medical

- Home & Garden

- Home Appliances

- Lights & Lighting

- Luggage, Bags & Cases

- Machinery, Hardware & Tools

- Measurement & Analysis Instruments

- Mechanical Parts & Fabrication Services

- Minerals & Metallurgy

- Office & School Supplies

- Packaging & Printing

- Rubber & Plastics

- Security & Protection

- Service Equipment

- Shoes & Accessories

- Sports & Entertainment

- Telecommunications

- Textiles & Leather Products

- Timepieces, Jewelry, Eyewear

- Tools

- Toys & Hobbies

- Transportation

Filters

Search

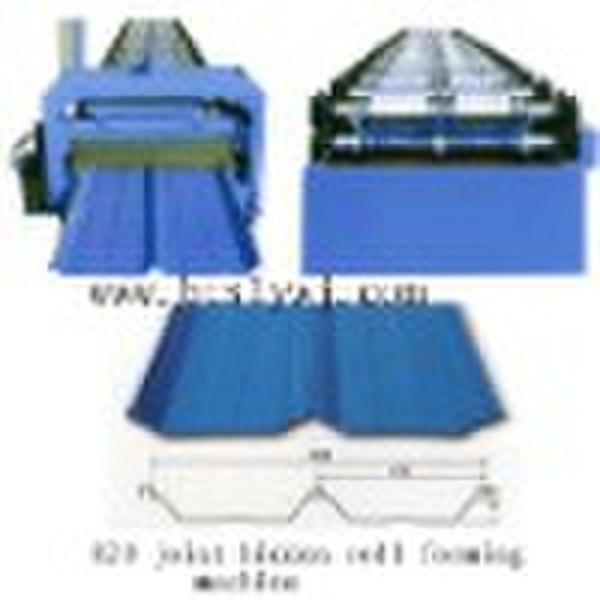

Joint-Hidden Roll Forming Machine

original price: 10 000 USD

Botou, China

Vita An

Contact person

Basic Information

cold roll forming machine joint-hiddenforming machine forming machine tiles making machine 1.Detailed Product Description Function and feature This producing line uses galvanized steel sheet, colored armor plate or aluminum plate as the material plate. The products of it are used as the roof tile and wall panel outside of building, to increase the beauty and durability of the roof tile and wall panel. This line has no limit on processing length; you can set several different data on the computer control cabinet according to your own need. After pressing the button "Confirm", the machine can produce the panel automatically according to the set data. The molding plate surface smooth and not easy to be marked when it is being stamped. So it is easy to install. The product conforms to National Steel Construction Building Standard. The forming rollers is the key of roll forming machine. We use CAD to design and manufacture the rollers. After CNC lathe, the forming rollers will be harden by vacuum heat treatment and finished the profiles again. These processes make the more accurate forming rollers ,avoid the deformation during heat treatment and ensure the rollers preciseness and wear-resisting abili 2.Processing technique and deployment: Processes: DecoilerRoll forming machinePLC systemHydraulic systempost cutOutput table 3.Components of line: No. NameUnitQty1Decoiler set 12Main machine for roll forming set 13Control system set 14Hydraulic system set 15Post cut set 16Output table set 1 4. Technical Specification (1) Manual Un-coiler(Option Hydraulic un-coiler) Un-powered; single head; max.capacity: 5000kg; Coil inner-diameter: 508mm (2) Roll-Forming M/C: Steps:13 Roller Material: 45# steel Voltage:380V/50Hz. line speed:3-6m/min; Rolling chromium thickness:0.05 mm (3)Pressing Die: Stop to press, Post to press Press tool material: 40Cr and heat-treated (4) Cutting Mechanism It adopts hydraulic drive and automatic location to decide the dimention and cut the target products. Match equipment : one set of cutting tool, one hydraulic tank ,one cutter machine. Stop to cut , Post cut cutting length tolerance: ±2mm Cutting tool material: GCr12 with quenched treatment 60-62 (5) Hydraulic System It is controlled by gear wheel oil pump. After filling the hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.Match equipment: a set of hydraulic tank , a set of hydraulic oil pump, two hydraulic pipes and two sets of electromagnetism valves.Power of the oil pump: 3kw Hydraulic oil :40# (6)Computer control cabinet: It adopts Taida PLC to control. The target piece length is adjustable and digit of it can be adjusted Computed mode has two modes: automatic and manual one. (7)Counter : One counter gauges length, pulses, and decides length

Delivery terms and packaging

Packaging Detail: main body of machine naked loaing in the container,only packed by plastic film.spare parts are put into a wooden box. Delivery Detail: within 30 days after we received the deposit

Port: Tianjin Port

Payment term

Letter of credit

Telegraphic transfer

-

Payment Methods

We accept: